-

Andres Blancoスラスターは正しく着きました。私はROVのそれらをテストし、私達は結果と非常に幸せです。エポキシの内部の終わりは非常によく、サイズに関連するモーターの力はかなりよいです。

Andres Blancoスラスターは正しく着きました。私はROVのそれらをテストし、私達は結果と非常に幸せです。エポキシの内部の終わりは非常によく、サイズに関連するモーターの力はかなりよいです。 -

グレゴアールLange常州のビック技術モーター技術と私達の会社間の協同はちょうど大きかったです。私達の必要性のよい理解、私達の問題を解決することを大きい決定。私は推薦します!

グレゴアールLange常州のビック技術モーター技術と私達の会社間の協同はちょうど大きかったです。私達の必要性のよい理解、私達の問題を解決することを大きい決定。私は推薦します! -

デイヴィッドMolevelt専門および明確なコミュニケーション。順序は時間に出荷されました。郵送物に加えられてところ反対のコネクター。私達が同意したように運転者の仕事!

デイヴィッドMolevelt専門および明確なコミュニケーション。順序は時間に出荷されました。郵送物に加えられてところ反対のコネクター。私達が同意したように運転者の仕事! -

Buildstormの私用限られたプロダクトは、それきちんと詰まりました予想通り働きます。販売人は非常にすぐに答え、購入の決定で助けます。それらはあなたのためのプロダクトをカスタマイズして準備ができています。

Buildstormの私用限られたプロダクトは、それきちんと詰まりました予想通り働きます。販売人は非常にすぐに答え、購入の決定で助けます。それらはあなたのためのプロダクトをカスタマイズして準備ができています。 -

Ashley Griffin郵送物は非常にすぐに受け取られました。プロダクトは包装によってよく保護されました。会社repは誠心誠意および親切でした。評価とA!

Ashley Griffin郵送物は非常にすぐに受け取られました。プロダクトは包装によってよく保護されました。会社repは誠心誠意および親切でした。評価とA!

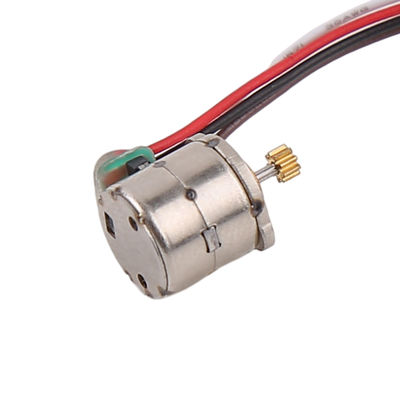

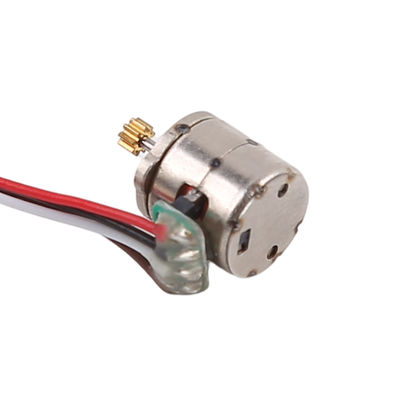

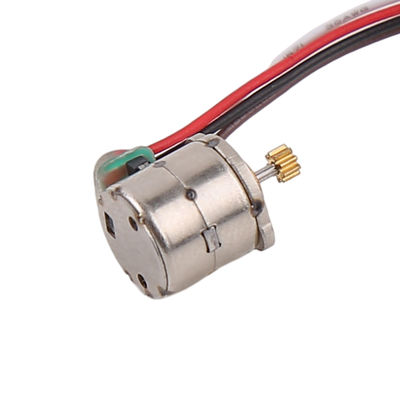

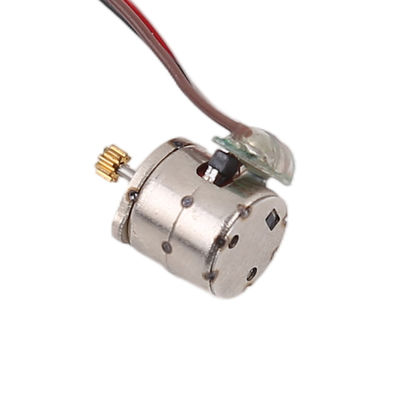

Vic-Tech 2 Phase 4 Wire Stepper Motor , 3.3V DV Stepping Motor 8mm

試供品およびクーポンのための私に連絡しなさい。

ワットサップ:0086 18588475571

微信: 0086 18588475571

スカイプ: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x| タイプ | 3.3 Vのステッピング モーター | ステップ角度(程度) | 18° |

|---|---|---|---|

| 電圧: | 3.3V DC | 段階: | 2段階 |

| 抵抗: | 40オーム | モーター直径 | 8mm |

| トルク | 0.9-1.2g.cm | 段階数 | 2段階 |

| ハイライト | 3.3V stepper motor 8mm,2 phase 4 wire stepper motor,micro stepper motor with warranty |

||

8mm micro stepper motor Long life 2 phase 4 wire 3.3V DC mini stepping motor

![]()

VSM08133 is a precision micro stepping motor body outer diameter 8MM, body length 8.2MM, shaft outer diameter 1MM, the shaft length can be changed according to the needs, and can be equipped with gears, pulleys,

Corresponding output devices such as worm and screw.

The motor has a basic step angle of 18 degrees and the motor runs 20 steps per week.

Because of its small size, high precision, and easy control, this miniature stepper motor is widely used in cameras, optical instruments, lenses, flashlights, precision medical equipment, automatic door locks and other fields.

The motor input part of the FPC, but can according to the customer demand can be changed to a connecting line needle, PCB and other forms.

The mounting bracket can be changed according to the customer's request.

At the same time, we can match the corresponding drive system to meet the needs of customers!

Our team has more than 10 years of stepper motor design, development and production experience, so we can achieve product development and auxiliary design according to the special needs of customers!

Customer needs are our efforts, please feel free to contact us!

This miniature motor is mainly used in cameras, lenses, optical instruments and other fields. The light needle is relatively small in size and the control is very precise. The needs of customers are the direction of our efforts, and meeting the needs of customers will be our highest pursuit. If you have needs, please feel free to keep in touch with us.

8mm micro stepper motor parameter sheet:

| PRODUCT NAME | 8 MM MICRO STEPPER MOTOR |

| MODEL | VSM08133 |

| RATED VOLTAGE | 3.3 V DC |

| COIL RESISTANCE | 40Ω±10% |

| NO.OF PHASES | 2 PHASES |

| STEP ANGLE | 18°/STEP |

| MAX. STARTING FREQUENCY | 1000 PPS min. (AT 3.3 V DC) |

| MAX. SLEWING FREQUENCY | 1200 PPS min. (AT 3.3 V DC) |

| PULL IN TORQUE | 0.8 gf-cm min. (AT 480 PPS , 3.3V DC) |

| PULL OUT TORQUE | 1.0 gf-cm min. (AT 480 PPS , 3.3V DC) |

| INSULATION CLASS | CLASS E FOR COILS |

| INSULATION STRENGTH | 100V AC FOR ONE SECOND(3mA MAX) |

| INSULATION RESISTENCE | 1 MΩ (DC 100 V) |

| OPERATING TEMPERATURE RANGE | -10~+60 ℃ |

| OEM & ODM SERVICE | AVAILABLE |

8mm micro stepper motor outside drawing:

![]()

Product display:

8mm Stepper Motor 3.3V DC 2 Phase 18 Degree Step Angle Micro Stepper Motor

![]()

The principle of stepper motor is as follows:

1. The stepper motor is controlled by pulse signal. Each time a pulse is input, the stepper motor is pushed forward one step.

2. The rotation step angle of the stepping motor is based on the structure of the motor and is realized in a certain proportion.

3. In practice, there will be slight differences in the rotation step angle of the motor. This is because the structure of the motor is fixed, and the total number of poles will not be accumulated, and the higher the processing accuracy will be. In general, the step angle of an industrial hybrid stepper motor is 1.8°, or 200 poles.